1.Advanced adsorption leading edge feed system, simple operation, high precision.

2. 7_inch true color touch screen can be installed to preset 200 sets of orders, order inquiry, zero order input, synchronous zeroing of the whole machine, automatic/manual adjustment, machine parameter management, uniform manual automatic control of lifting and dropping plates, automatic display of production quantity and production speed, as well as the setting of production quantity

3.All the rotating rollers are made of high-quality steel, plated with hard chromium and ground on the surface. The rotating gear is made of high quality alloy steel after heat treatment and grinding.

4. The clearance adjustment adopts the self-locking adjustment of the high-precision turbine box, and is equipped with the three-bar disc handle seat, which is convenient and fast.

5. The slotting part adopts electric control to adjust the axial, longitudinal and box height dimensions of each cutter base、

6. Die cutting speed compensation system, cam-type soft roller lateral travel 40 mm, rubber pad wear uniform, improve the use of rubber pad, reduce the cost.

7. Using the down insert paper, not because the cardboard is hard or not because and collapse. thus improving the stability of the paper out of the equipment, to ensure the quality of the sticky box.

8. PLC program control, automatic adjustment according to the input order parameters.

9. The equipment has secondary indentation and right-angle finishing mechanism, whose performance is stable and reliable which can perfectly control the size of the folded gap.

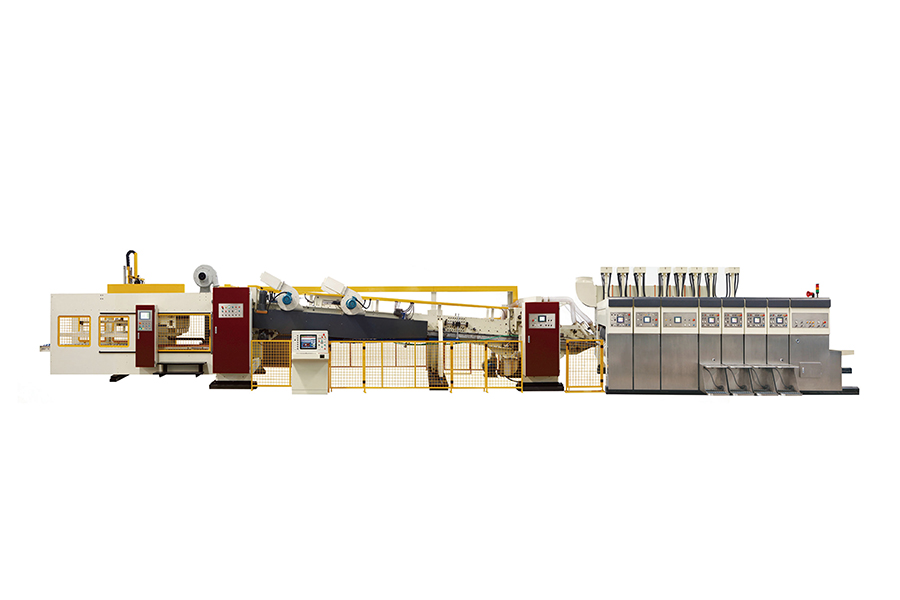

Main structure

1.The bottom folding box gluing machine adopts the bottom inserting paper,which will not collapse because of the cardboard is hard or not stuck firmly.thus improving stability of the paper gluing machine and ensuring the quality of the box gluing.

2. PLC program control, automatic adjustment according to the input order parameters

3.The equipment has secondary indentation and right-angle finishing mechanism, whose performance is stable and reliable, which can perfectly control the size of the folded gap.

4.The right-angle finishing mechanism of the equipment driven by a separate motor,which ensures the purity of power and stable and reliable operation. Even if the slot pressing line is not good, through our secondary pressing line and right-angle finishing mechanism, also can control the adhesive cap,the sizes even, the cap size can be arbitrarily adjusted.

5. The secondary alignment mechanism can completely solve the scissors difference, A secondary alignment mechanism is arranged at the position of stacking counting.