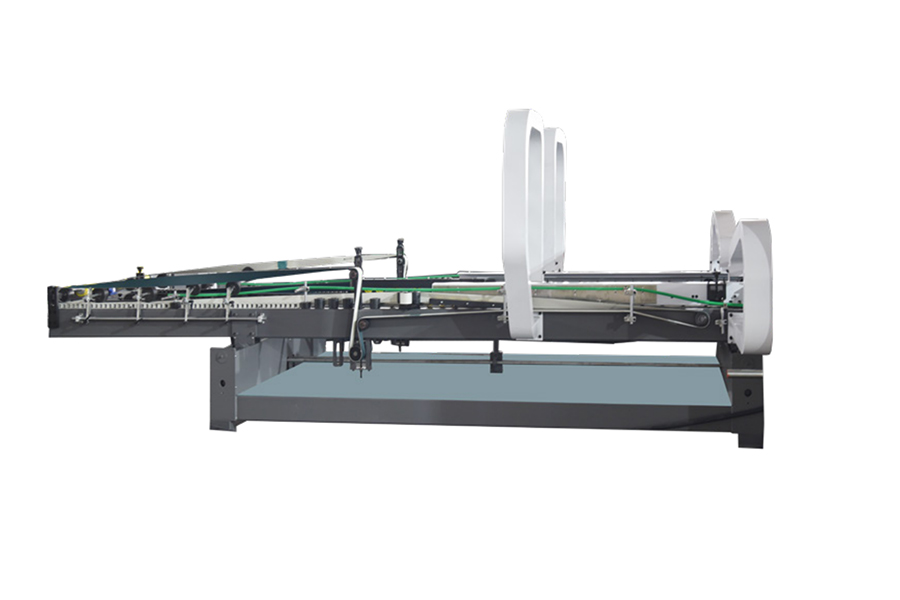

USES and feature

YD series automatic box gluing machine consists of three parts: vacuum feeding part, gluing folding part and counting stacking output part group formation. Digital display control, PLC computer amplitude modulation, dual frequency synchronous operation, with simple,fast, reliable and accurate operation control mode.Automatic paper feeding, automatic gluing and folding, automatic counting, automatic stacking output,average gluing speed of 150 m Per minute, high speed energy saving,labor cost saving

Workflow and Benefits

Paper feeding department

1.Adopt the belt leading edge suction paper feeding method, accurate and reliable

2.Adopt high-grade electromagnetic clutch and electromagnetic brake system,which can supply paper Single control, single reliable operation room

3.The height of the paper pressing wheel can be adjusted, and the thickness of the paper board is2-8mm.

4.Linkage with folding part, frequency conversion speed regulation, paper feeding speed 0-150m/min.

5.The front baffle of the paper feeding department and the paper feeding belt can be adjusted left and right.

Gluing and folding department

1.The main motor adopts frequency conversion speed regulation system, which is noiseless flexible and stable.

2.Adopt imported high-friction belt to transport cardboard, automatically fold

3.Stainless steel wheel is used for glue coating,with even glue quantity, trouble-free and glue saving

4.The folding part is equipped with board correction device and indentation correction device.

5.The folding part has two rows of adjustable inner positioning regulating wheel system, so the forming precision is higher

6.Folding speed 0-150 m/min

Counting and stacking department

1.Automatic stacking and neat output

2.The main motor of the technical department is variable frequency,with adjustable speed and stable and reliable starting

3.Transport cartons by belts, stacking neatly,0-130 m/min

4.Use slapping board to hit large cartons, which has the function of rectifying deviation and small deviation.

5.Pneumatic counting and launching, PLC electronic control, reliable,accurate and fast action.

6.Using PLC programming controller and touch screen digital control simple operation, reliable action does not stop the input data, automatic count.

7.The output part adopts the synchronous compression method of the bottom conveyor belt and the upper compression belt, so that the finished cartons are glued firmly and neatly without dislocation output.

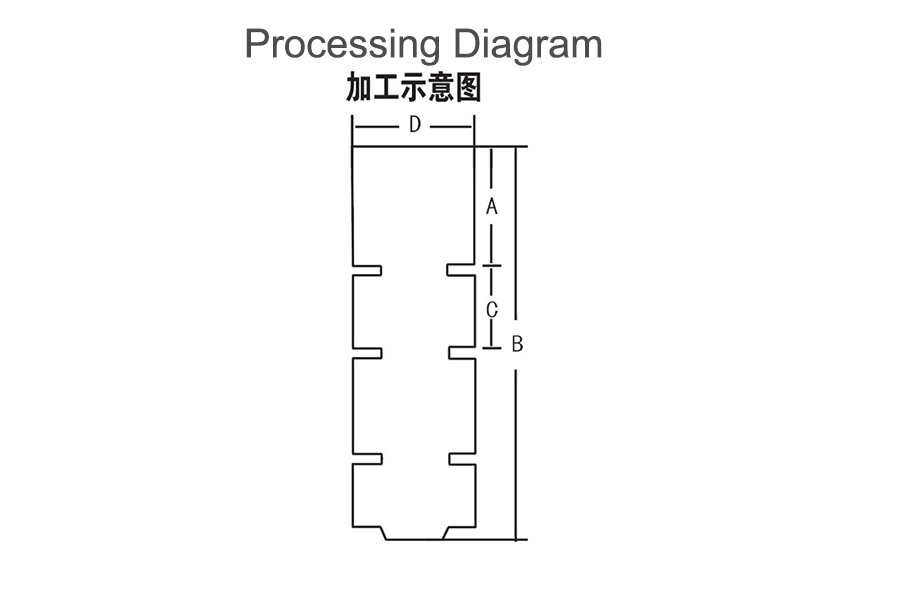

| Model | QZD-2600 |

|---|---|

Size A (mm) | 80-800 |

Size B (mm) | 420-2600 |

Size C (mm) | 130-840 |

Size D (mm) | 170-1200 |

Install Area (mm) | 4000 x 15000 |

Motor Kw | 10 kw |